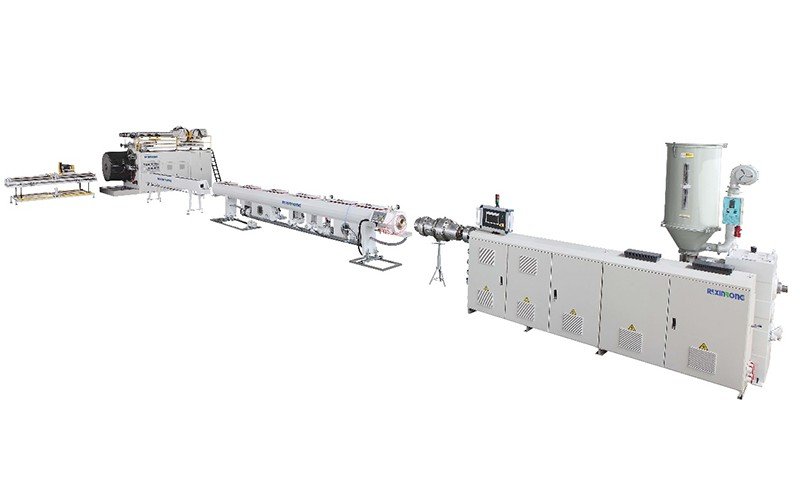

Steel wire skeleton reinforced plastic composite pipe machine

Steel wire skeleton reinforced plastic composite pipe machine is widely used in industry, city water supply, gas, chemical and agriculture, etc. This line can use strong steel wire, glass fiber bunch and PET to produce strong composite plastic pipe. It can produce polyethylene water or gas pipe too. It’s multi-purpose to save investment. The pipe has advantage of high pressure, less needed materials and unstratified, tec. The standard was applied and enforced in year 2004. The corresponding engineering regulations and fittings are well completed. The manufacturing, sales and promotion has been step-by-step on the road of industrialization development. It becomes main product of composite pipes.

Technical Data

| Model | Pipe Range(mm) | Line speed(m/min) | Total Installation Power(kw |

| LSSW160 | 中50- φ160 | 0.5-1.5 | 200 |

| LSSW250 | φ75- φ250 | 0.6-2 | 250 |

| LSSW400 | φ110- φ400 | 0.4-1.6 | 500 |

| LSSW630 | φ250- φ630 | 0.4-1.2 | 600 |

| LSSW800 | φ315- φ800 | 0.2-0.7 | 850 |

| Pipe Size | HDPE Solid Pipe | Steel wire skeleton reinforced plastic composite pipe | ||

| Thickness(mm) | Weight(kg/m) | Thickness(mm) | Weight(kg/m) | |

| φ200 | 11.9 | 7.05 | 7.5 | 4.74 |

| φ500 | 29.7 | 43.80 | 15.5 | 25.48 |

| φ630 | 37.4 | 69.40 | 23.5 | 40.73 |

| φ800 | 47.4 | 112.00 | 30.0 | 75.39 |

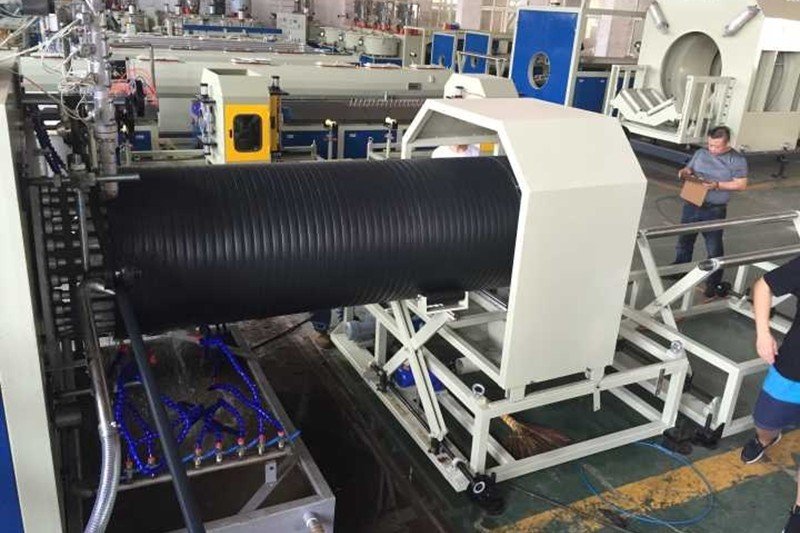

HDPE hollow wall winding pipe machine

HDPE hollow wall winding pipe machine is used to make pipes used for water drainage and sewage in many fields, such as municipal construction, residential districts, highways and bridges, etc.

Hollow wall winding pipe is mainly used for sewage system, same as double wall corrugated pipe. Compared with double wall corrugated pipe, it has advantages of low machine investment cost and larger pipe diameter.

Our PE hollow winding pipe extrusion line can process several kinds of material, including HDPE, PP, etc, size from minimum 200mm to 3200mm with single layer or multi-layer.

Changing some parts can produce different shape of pipe or profile to form different kinds of spiral pipe.

◆The first extruder produce rectangular pipe into winding forming machine, the second extruderproduce plastic bar, then the plastic bar is pressed on the rectangular pipe and winding pipecomes out.Outside and inside of winding pipe is smoolh and neat.

◆ It adopts spiral die head and two extruder charging, realizing spiral rotational forming.

◆ The advanced PLC computer control system makes it easy to operate. It’s stable and reliable.

◆ With different design of profile tube it can produce pipes of dfrerent ring stfness that audapt todiferet conditions and felds.

◆ High eficiency single screw extruder(using gramule material) and energy-saving twin screwextruder (using powder or granule material forchoice.

◆ Changing some parts can also produce metal square proftle renforced spiral pipe.

◆ A complete range of specification, pipe range: ID200mm -ID3200om

Details

Single Screw Extruder

Based on 33:1 L/D ratio for screw design, we have developed 38:1 L/D ratio. Compared with 33:1 ratio, 38:1 ratio has advantage of 100% plasticization, increase output capacity by 30%, reduce power consumption up to 30% and reach almost linear extrusion performance.

Winding Machine

Winding machine is used to wind square pipe and attach them together to form spiral pipe. It is adjustable to produce different spiral pipe sizes, also winding angel is adjustable for square pipe in different width. With effective water cooling.

Cutter

Cutter controlled by Siemens PLC with fully automatic cutting process, which can customize cutting length.

Precision Guide Rail

Apply linear guide rail, cutting trolly will move along guide rail. Cutting process stable and cutting length accurate.

Industrial dust collector

With powerful industrial dust collector for option to absorb dust.

Stacker

To support pipes, with rubber support roller, roller will rotate along with the pipe.

Roller motor

For big size spiral pipe, apply motor to drive roller rotating along with pipe.

Central Height Adjustment

For big size spiral pipe, apply motor to adjust central height, easier and faster.

Technical Data

| Model | Pipe Range(mm) | Output Capacity(kg/h) |

Total power(kw) |

|

| ID(min) | OD(max) | |||

| ZKCR800 | 200 | 800 | 100-200 | 165 |

| ZKCR1200 | 400 | 1200 | 150-400 | 195 |

| ZKCR1800 | 800 | 1800 | 300-500 | 320 |

| ZKCR2600 | 1600 | 2600 | 550-650 | 400 |

| ZKCR3200 | 2000 | 3200 | 600-1000 | 550 |

PE Carbon Spiral Reinforced Pipe Extrusion Line

| MODEL | SJ90/30 | SJ65/30B |

| PIPE DIAMETER | 50-200 | 20-125 |

| CALIBATE UNIT | SGZL-200 | SGZL-125 |

| HAUL-OFF MACHINE | SLQ-200 | SLQ-200 |

| WINDING MACHINE | SQ-200 | SQ-200 |

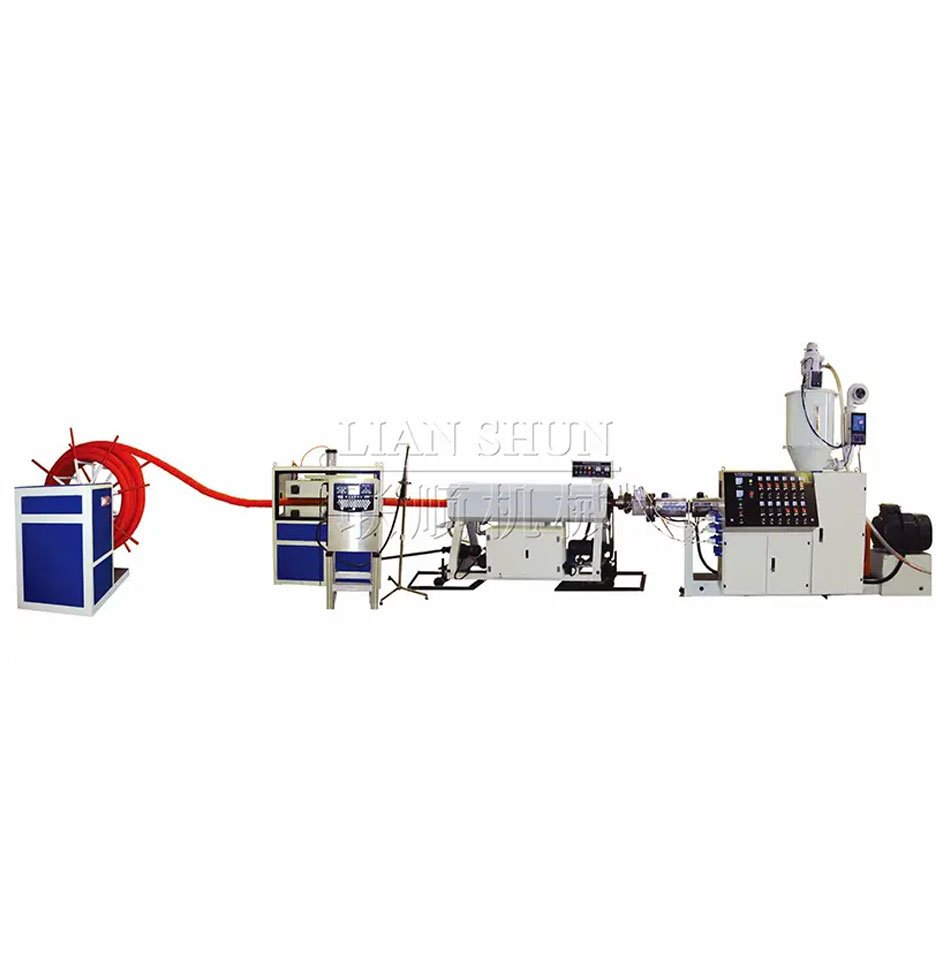

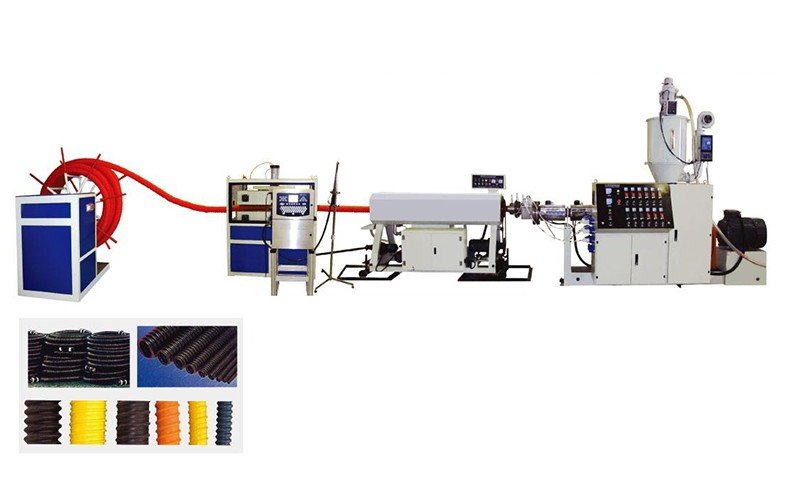

PVC Spiral Hose Extrusion Line

| Model | SJ45 | SJ65 |

| Extruder | SJ45/28 | SJ65/28 |

| Dlameter Range(mm) | φ12- φ50 | φ63- φ200 |

| Output(kg/h) | 20-40 | 40-75 |

| Installed Power(kw) | 35 | 50 |

PVC Fiber Reinforced Hose Extrusion Line

| Extruder | Pipe diameter | Capacity | Installed power | Average energy consumption | size |

| SJ-45×30 | <6-25mm | 35-65kg/h | 39.9kw | 27.5kw | 1.2*3*1.4 |

| SJ-65×30 | <8-38mm | 40-80kg/h | 66.3kw | 39.78kw | 1.3*4*5 |

| extruder | Haul-off unit | Braider | Cooling machine | Drying tank | winder |

| 2 sets | 2 sets | 1 set | 2 sets | 1 set | 1 set |

PVC Steel Reinforced Hose Extrusion Line

| Model | SJ45 | SJ65 | SJ90 | SJ120 |

| Extruder | SJ45/30 | SJ65/30 | SJ90/30 | SJ120/30 |

| Dlameter Range(mm) | φ12- φ25 | φ20- φ50 | φ50- φ110 | φ75- φ150 |

| Output(kg/h) | 20-40 | 40-75 | 70-130 | 100-150 |

| Installed Power(kw) | 30 | 40 | 50 | 75 |