Short Description

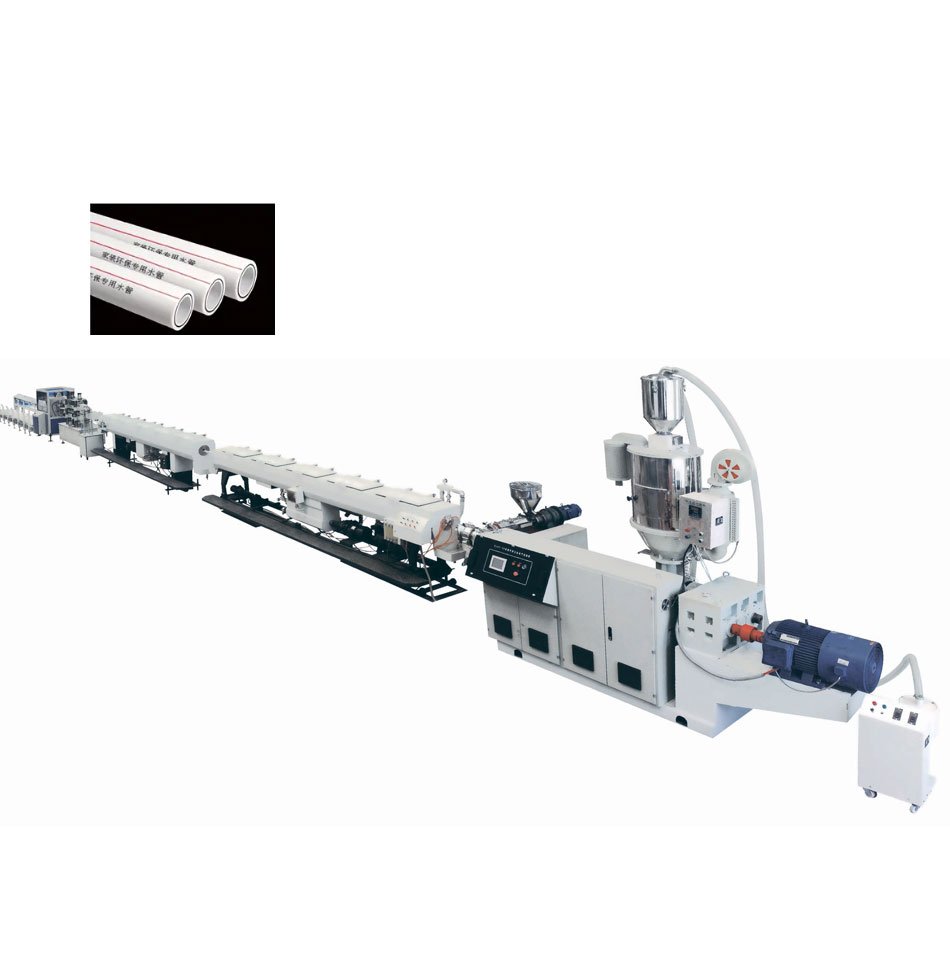

PPR pipe machine is mainly used to produce PPR hot and cold water pipes. PPR pipe extrusion line is composed of extruder, mold, vacuum calibration tank, spray cooling tank, haul off machine, cutting machine, stacker and so on. PPR pipe extruder machine and haul off machine adopt frequency speed regulation, PPR pipe cutter machine adopts chipless cutting method and PLC control, fixed-length cutting, and cutting surface is smooth.

Application

PPR pipes can be used for the following applications:

Conveyance of potable water

Hot and cold water transportation

Underfloor heating

Central heating installations in houses and industries

Industrial transportations (chemical fluids and gasses)

Compared with PE pipe, PPR pipe can be used to transport hot water. Usually, it is used inside building for hot water supply. Nowadays, there are many kinds of PPR pipe, for example, PPR fiberglass composite pipe, also PPR with uvioresistant outer layer and antibiosis inner layer.

Features

1. Three- layer co-extrusion die head, thickness of each layer is uniform

2. PPR fiberglass composite pipe has high strength, small deformation at high temperature, low expansion coefficient. Compared with PP-R pipe, PPR fiberglass composite pipe saves cost 5%-10%。

3. The line adopts PLC control system with HMI which is easy to operate and has function of linkage.

Details

Single Screw Extruder

Based on 33:1 L/D ratio for screw design, we have developed 38:1 L/D ratio. Compared with 33:1 ratio, 38:1 ratio has advantage of 100% plasticization, increase output capacity by 30%, reduce power consumption up to 30% and reach almost linear extrusion performance.

Simens Touch Screen and PLC

Apply program developed by our company, have English or other languages to be input into the system.

Spiral Structure of Barrel

Feeding part of barrel use spiral structure, to ensure material feed in stable and also increase feeding capacity.

Special Design of Screw

Screw is designed with special structure, to ensure good plasticization and mixing. Unmelted material can not pass this part of screw.

Air Cooled Ceramic Heater

Ceramic heater ensure long working life. This design is to increase the area which heater contact with air. To have better air cooling effect.

High Quality Gearbox

Gear accuracy to be ensured 5-6 grade and lower noise below 75dB. Compact structure but with high torque.

Extrusion Die Head

Extrusion die head/mold apply spiral structure, each material flow channel is placed evenly. Each channel is after heat treatment and mirror polishing to ensure material flow smoothly. Die with spiral mandrel, it ensures no delay in the flow channel which can improve pipe quality. Particular disc design on calibration sleeves ensures high speed extrusion. Die head structure is compact and also provide stable pressure, always from 19 to 20Mpa. Under this pressure, pipe quality is good and very little effect on the output capacity. Can produce single layer or multi-layer pipe.

CNC Processing

Every part of extrusion die head is processed by CNC to ensure precision.

High Quality Material

Apply high quality material for extrusion die head. Die head has high strength and will not deform during long time use under high temperature condition.

Smooth Flow Channel

Have mirror polishing on flow channel and every part which contacts with melt. To make material flow smoothly.

Vacuum Calibration Tank

Vacuum tank is used to shape and cool pipe, so as to reach standard pipe size. We use double-chamber structure. First chamber is in short length, to ensure very strong cooling and vacuum function. As calibrator is placed in the front of first chamber and pipe shape is formed mainly by calibrator, this design can ensure quick and better forming and cooling of pipe. Double-strand vacuum tank is controlled individually, which makes convenient operation as single one. Stable and reliable pressure transmitter and vacuum pressure sensor are adopted to realize automatic control.

Special Design of Calibrator

Calibrator is specially designed to make more pipe area touches with cooling water directly. This design make better cooling and forming of square pipes.

Automatic Vacuum Adjusting System

This system will control vacuum degree within set range. With inverter to control vacuum pump speed automatically, to save power and time for adjustment.

Silencer

We place silencer on the vacuum adjust valve to minimize noise when air come into the vacuum tank.

Pressure Relief Valve

To protect the vacuum tank. When vacuum degree reach maximum limitation, the valve will open automatically to decrease vacuum degree to avoid broken of tank. Vacuum degree limitation can be adjusted.

Automatic water control system

Special designed water control system, with water continuously enter in and water pump to drain hot water out. This way can ensure low temperature of water inside chamber. Whole process is fully automatic.

Water, Gas Separator

To separate the gas water water. Gas exhausted from upside. Water flow into the downside.

Centralized Drainage Device

All water drainage from vacuum tank are integrated and connected into one stainless pipeline. Only connect the integrated pipeline to outside drainage, to make operation easier and faster.

Half Round Support

Half round support is processed by CNC, to ensure it can fit pipe exactly. After pipe moves out from calibration sleeve, the support will ensure pipe roundness inside vacuum tank.

Spray Cooling Water Tank

Cooling tank is used to cool pipe further.

Water Tank Filter

With filter in the water tank, to avoid any big impurities when outside water comes in.

Quality Spray Nozzle

Quality spray nozzles have better cooling effect and not easy blocked by impurities.

Double Loop Pipeline

Ensure continuous water supply to the spray nozzle. When the fliter blocked, the other loop can used to supply water temporarily.

Pipe Support Adjusting Device

With handwheel to adjust position of the up and down nylon wheel to keep pipe in the central line all the time.

Haul Off Machine

Haul off machine provides sufficient traction force to pull pipe stably. According to different pipe sizes and thickness, our company will customize traction speed, number of claws, effective traction length. To ensure match pipe extrusion speed and forming speed, also avoid deformation of pipe during traction.

Separate Traction Motor

Each claw has its own traction motor, controlled individually which makes convenient operation as single strand, additionally, with the upper caterpillar belt stop device, to ensure roundness of pipe. Customers can also choose servo motor to have bigger traction force, more stable traction speed and wider range of traction speed.

Separate Air Pressure Control

Each claw with it own air pressure control, more accurate, operation is easier.

Pipe Position Adjustment

Specially designed position adjustment system can make tube in the central of haul off unit.

Cutting Machine

PPR pipe cutting machine also called PPR pipe cutter machine is controlled by Siemens PLC, working together with haul off unit to have precise cutting. Use blade type cutting, pipe cutting surface is smooth. Customer can set the length of pipe they want to cut. With individual designed of chipless cutter. Driven by motor and synchronous belts which ensures normal cutting during high speed running.

Aluminum Clamping Device

Apply aluminum clamping device for different pipe sizes, eash size has it own clamping device. This structure will make pipe stay in the central exactly. No need to adjust the central height of clamping device for different pipe sizes.

Precision Guide Rail

Apply linear guide rail, cutting trolly will move along guide rail. Cutting process stable and cutting length accurate.

Blade Adjustment System

With ruler to show different position of blade to cut different pipe size. Easy to adjust blade position.

Stacker

To support and unload pipes. Length of stacker can be customized.

Pipe surface protection

With roller, to protect pipe surface when moving pipe.

Central Height Adjustment

With simple adjustment device to adjust the central height for different pipe sizes.

Technical Data

| Model | Pipe diameter scope | Host mode | Production capacity | Installed power | Production line length |

| PP-R-63 | 20-63 | SJ65,SJ25 | 120 | 94 | 32 |

| PP-R-110 | 20-110 | SJ75,SJ25 | 160 | 175 | 38 |

| PP-R-160 | 50-160 | SJ90,SJ25 | 230 | 215 | 40 |

| PE-RT-32 | 16-32 | SJ65 | 100 | 75 | 28 |