Short Description

Single screw plastic extruder machine can process all kind of plastics products, such as pipes, profiles, sheets, boards, panel, plate, thread, hollow products and so on. Single screw extruder is also used in graining. Single screw extruder machine design is advanced, production capacity is high, plasticization is good, and energy consumption is low. This extruder machine adopts hard gear surface for transmission. Our extruder machine have a lot of advantages.

Characteristics

Single screw plastic extruder machine can process all kind of plastics products, such as pipes, profiles, sheets, boards, panel, plate, thread, hollow products and so on. Single screw extruder is also used in graining. Single screw extruder machine design is advanced, production capacity is high, plasticization is good, and energy consumption is low. This extruder machine adopts hard gear surface for transmission. Our extruder machine have a lot of advantages.

We also manufacture many kinds plastic extruders such as sj25 mini extruder, small extruder, lab plastic extruder, pellet extruder, double screw extruder, PE extruder, pipe extruder, sheet extruder, pp extruder, Polypropylene Extruder, pvc extruder and so on.

Advantages

1. Long groove between feed throat and screw to improve output highly

2. Accurate temperature control system on feed section to match different plastics

3. Unique screw design to achieve higher plasticizing and products quality

4. Gearbox of high torsion balance to realize stable running

5. H shape frame to decrease vibrating

6. PLC operation panel to ensure synchronization

7. Energy conservation, easy for maintenance

Details

Single Screw Extruder

Based on 33:1 L/D ratio for screw design, we have developed 38:1 L/D ratio. Compared with 33:1 ratio, 38:1 ratio has advantage of 100% plasticization, increase output capacity by 30%, reduce power consumption up to 30% and reach almost linear extrusion performance.

Simens Touch Screen and PLC

Apply program developed by our company, have English or other languages to be input into the system

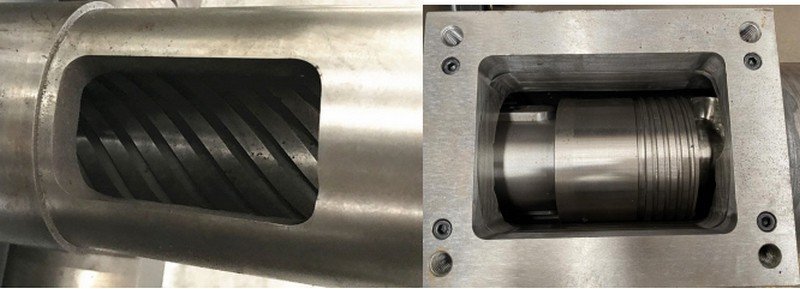

Special Design of Screw

Screw is designed with special structure, to ensure good plasticization and mixing. Unmelted material can not pass this part of screw, good plastic extrusion screw

Spiral Structure of Barrel

Feeding part of barrel use spiral structure, to ensure material feed in stable and also increase feeding capacity.

Air Cooled Ceramic Heater

Ceramic heater ensure long working life. This design is to increase the area that heater contact with air to have better air cooling effect.

High Quality Gearbox

Gear accuracy to be ensured 5-6 grade and lower noise below 75dB. Compact structure but with high torque.

Technical Data

|

Model |

L/D |

Capacity(kg/h) |

Rotary speed(rpm) |

Motor power(KW) |

Central height(mm) |

|

SJ25 |

25/1 |

5 |

20-120 |

2.2 |

1000 |

|

SJ30 |

25/1 |

10 |

20-180 |

5.5 |

1000 |

|

SJ45 |

25-33/1 |

80-100 |

20-150 |

7.5-22 |

1000 |

|

SJ65 |

25-33/1 |

150-180 |

20-150 |

55 |

1000 |

|

SJ75 |

25-33/1 |

300-350 |

20-150 |

110 |

1100 |

|

SJ90 |

25-33/1 |

480-550 |

20-120 |

185 |

1000-1100 |

|

SJ120 |

25-33/1 |

700-880 |

20-90 |

280 |

1000-1250 |

|

SJ150 |

25-33/1 |

1000-1300 |

20-75 |

355 |

1000-1300 |