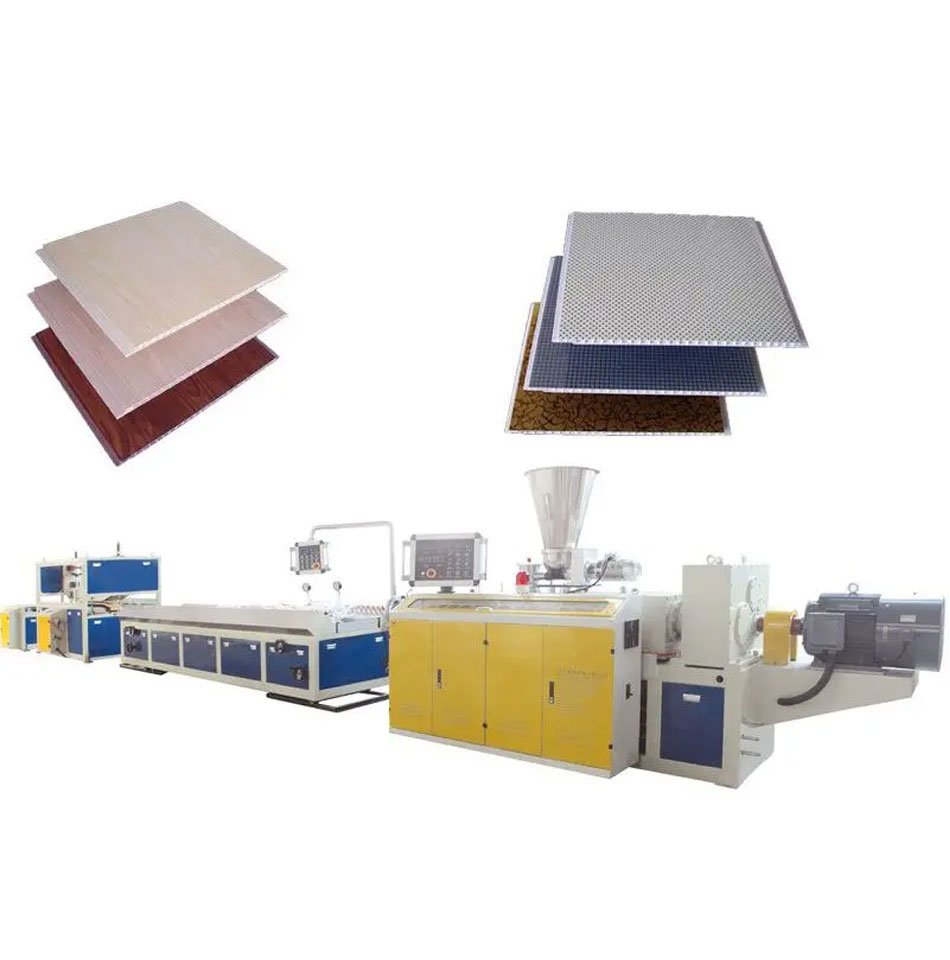

High Output PVC Ceiling Extrusion Line

Short Description

Application

PVC ceiling machine is used to produce PVC ceilings, PVC panels, PVC wall panels.

Process Flow

Screw Loader for Mixer→ Mixer unit→ Screw Loader for Extruder→ Conical Twin Screw Extruder → Mold → Calibration Table→ Haul off machine→ Cutter machine→ Tripping Table → Final Product Inspecting &Packing

Advantages

According to different cross section, die dead and customer’s requirements, pvc extruder of different specification will be chosen together with matching vacuum calibrating table, lamination machine, haul off machine, cutting machine, stacker, etc. Special designed vacuum tank, haul off and cutter with saw dust collecting system guarantee fine product and stable production.

Details

Conical Twin Screw Extruder

Conical twin screw extruder is used to produce PVC panels. With latest technology, to lower power and ensure capacity. According to different formula, we provide different screw design to ensure good plasticizing effect and high capacity.

Mold

Extrusion die head channel is after heat treatment, mirror polishing and chroming to ensure material flow smoothly.

High-speed cooling forming die supports the production line with faster linear speed and higher efficiency;

According to the samples and drawings provided by customers, product design, mold manufacturing and processing production.

Calibration Table

Calibration table is adjustable by fore-back, left-right, up-down which brings simplified and convenient operation;

• Include full set of vacuum and water pump

• Length from 4m-11.5m;

• Independent operation panel for easy operation

Haul off machine

Each claw has its own traction motor, in case when one traction motor stop working, other motors can still work. Can choose servo motor to have bigger traction force, more stable traction speed and wider range of traction speed.

Equipped with meter counter; There are different models according to the profile size

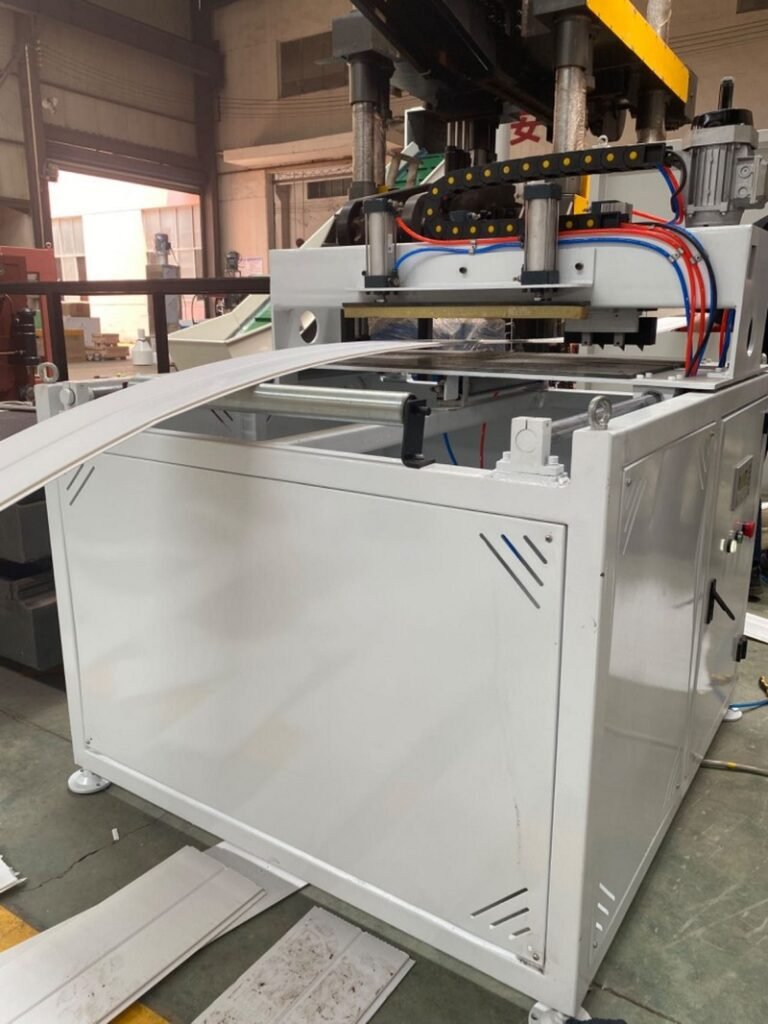

Cutter machine

Saw cutting unit brings speedy and stable cutting with smooth incision. We also offer hauling and cutting combined unit which is a more compact and economical design.

The moving speed of the cutting machine is synchronized with the pulling speed, the operation is stable, and it can be automatically cut to length.

Technical Data

| Model | SJZ51 | SJZ55 | SJZ65 | SJZ80 |

| Extruder model | Ф51/105 | Ф55/110 | Ф65/132 | Ф80/156 |

| Main moror power(kw) | 18 | 22 | 37 | 55 |

| Capacity(kg) | 80-100 | 100-150 | 180-300 | 160-250 |

| Production width | 150mm | 300mm | 400mm | 700mm |