PE PP Pelletizer Machine

Description

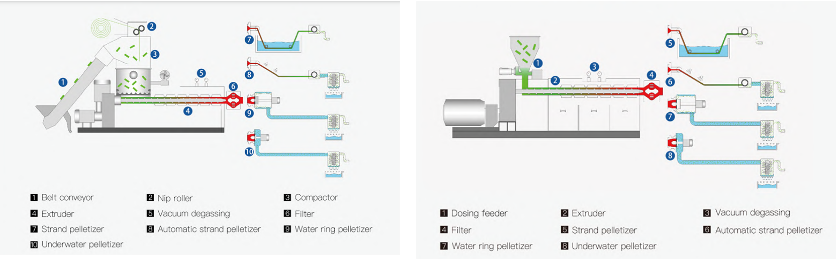

Plastic pelletizer machine is the process of converting plastics into granules. In operation, the polymer melt is divided into a ring of strands that flow through an annular die into a cutting chamber flooded with process water. A rotating cutting head in the water stream cuts the polymer strands into pellets, which are immediately conveyed out of the cutting chamber.

Plastic pelletizing plant can be customized as single (only one extrusion machine) and double stage arrangement (one main extrusion machine and one smaller secondaty extrusion machine).

“Hot Cut” water-ring die face pelletizing and “Cold Cut” strand pelletizing methods are available depending on your preference.

Melt pelletizing (hot cut). Melt coming from a die that is almost immediately cut into pellets that are conveyed and cooled by liquid or gas.

Strand pelletizing (cold cut). Melt coming from a die head is converted into strands that are cut into pellets after cooling and solidfication.

We can manufacture good pelletizer machine for you with good pelletizer machine price.

Details

Compactor Unit

The combination of high speed rotatory blades and stationary blades quickens the speed of compacting and directing materials into extruder screws.

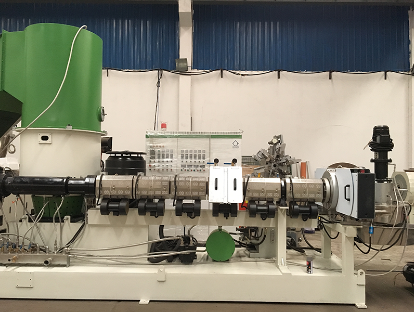

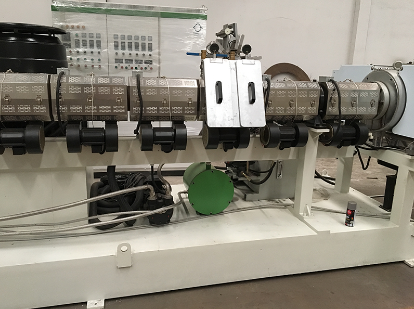

Extruder Unit

A specialized single screw extruder applied to gently melt the pre-compacted material.

The plastic scraps will be well melted, plasticized in the extruder.

High efficient barrel and screw used for extruder with excellent plastizing result and high output capacity, adopt high wear resistant alloy material to ensure 1.5 times service life of normal one.

Degassing unit

With a double-zone vacuum degassing system, most volatiles can be removed effectively, especially heavy printed film and material with some water content.

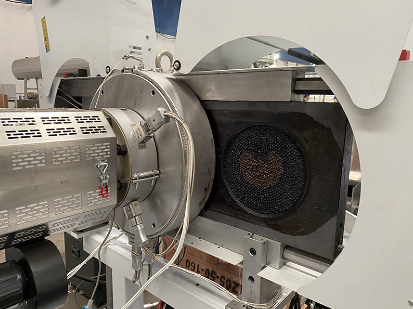

Filter

Plate type, pistion type and automatic self-cleaning type filter, Different choice according to impurity contents in material and client’s habit.

Plate type filter is cost-effective and easy to operate which mainly used for regular thermoplastic as usual filtration solution.

Water ring pelletizer

Cutting speed of pelletizer controlled automatically by PLC according to the pressre of die head, which could achieve the uniform size for outut pellets.

Blades of pelletizer touch to die plate automatically by pneumatic system, make sure blades

contact with die plate properly, easy to operate and abrasion avoided.

Technical Data

| Type | KCP80 | KCP100 | KCP120 | KCP140 | KCP160 | KCP180 | |

| Capacity(kg/h) | 150-250 | 300-420 | 400-600 | 600-750 | 800-950 | 1000-1200 | |

| Energy consumption(kWh/kg) | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | |

| Compactor | Volume(L) | 300 | 500 | 800 | 1000 | 1200 | 1400 |

| Motor Power(kw) | 37-45 | 55-75 | 75-90 | 90-132 | 132-160 | 160-185 | |

| Extruder | Screw Diameter(mm) | φ80 | φ100 | φ120 | φ140 | φ160 | φ180 |

| L/D | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | |

| Motor power(kw) | 55-75 | 90-110 | 132-160 | 160-200 | 250-315 | 315-355 | |

| Filter(options) | Two position plate type | • |

• |

• |

• |

• |

• |

| Two position piston type | ◦ |

◦ |

◦ |

◦ |

◦ |

◦ |

|

| Back flush piston type | ◦ |

◦ |

◦ |

◦ |

◦ |

◦ |

|

| Automatic selfcleaning type | ◦ |

◦ |

◦ |

◦ |

◦ |

◦ |

|

| 2nd Extruder(optional) | Screw Diameter(mm) | φ100 | φ120 | φ150 | φ150 | φ180 | φ200 |

| L/D | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | |

| Motor power(kw) | 37-45 | 45-55 | 55-75 | 75-90 | 90-110 | 110-160 | |

| Downstream(options) | Water ring pelletizer | • |

• |

• |

• |

• |

• |

| Strand pelletizer | ◦ |

◦ |

◦ |

◦ |

◦ |

◦ |

|

| Automatic strand pelletizer | ◦ |

◦ |

◦ |

◦ |

◦ |

◦ |

|

| Underwater pelletizer | ◦ |

◦ |

◦ |

◦ |

◦ |

◦ |